As NonFM prepares to commission its next-generation mineral recovery facility in New Mexico, the company is spotlighting one of its core technologies: froth flotation. Often associated with traditional ore processing, flotation is now playing a critical role in extracting valuable metals from old smelter slag, a resource long dismissed as industrial waste.

Slag: A Hidden Resource

Smelter slag is the glassy byproduct formed when ore is processed at high temperatures to separate metals from impurities. While most primary metals are recovered during smelting, significant quantities of valuable minerals—including copper, lead, zinc, gold, silver, and platinum group metals (PGMs)—remain trapped in the slag matrix. These are often too fine, oxidized, or encapsulated to be recovered through standard gravity or magnetic separation.

This is where flotation comes in.

How Flotation Works in Slag Recovery

Froth flotation is a process that separates hydrophobic (water-repellent) materials from hydrophilic ones using air bubbles and chemical reagents. In the context of slag processing, flotation offers a powerful way to:

- Liberate and concentrate fine metal particles such as sulfides, oxides, and residual matte

- Recover encapsulated metals by breaking down slag glass structure through milling

- Target specific mineral species using selective collectors, pH modifiers, and frothers

- Achieve economic recovery from low-grade or heterogeneous feedstocks

By adjusting reagents and flotation parameters, NonFM can tailor the process to recover multiple metals simultaneously, including copper, nickel, and even trace PGMs.

Why Flotation is Superior for Slag

While gravity and magnetic methods are effective for coarse particles and ferromagnetic materials, flotation shines in recovering ultrafine, oxidized, and chemically altered particles, which are common in slag. In many cases, flotation can extract metal values that represent 1–3% of slag mass—yet up to 60–80% of its economic value.

In field tests, NonFM’s flotation system has recovered:

- Over 90% of residual copper from finely milled smelter slag

- Significant concentrations of zinc and lead, often overlooked by gravity-based systems

- Fine particles of PGMs such as palladium and platinum, especially when pretreated by thermal or chemical activation

Environmental and Economic Impact

Flotation doesn’t just increase recovery—it reduces waste. Instead of stockpiling or landfilling slag, NonFM turns it into marketable concentrates and neutralized tailings suitable for construction materials. This aligns with growing regulatory and environmental pressure to rehabilitate contaminated slag piles and reduce tailings volume.

In economic terms, flotation:

- Lowers the threshold for viable metal recovery

- Increases profit margins on slag previously considered inert

- Creates opportunities for carbon credit and ESG incentives by reducing raw ore dependency

Flotation: Part of a Hybrid System

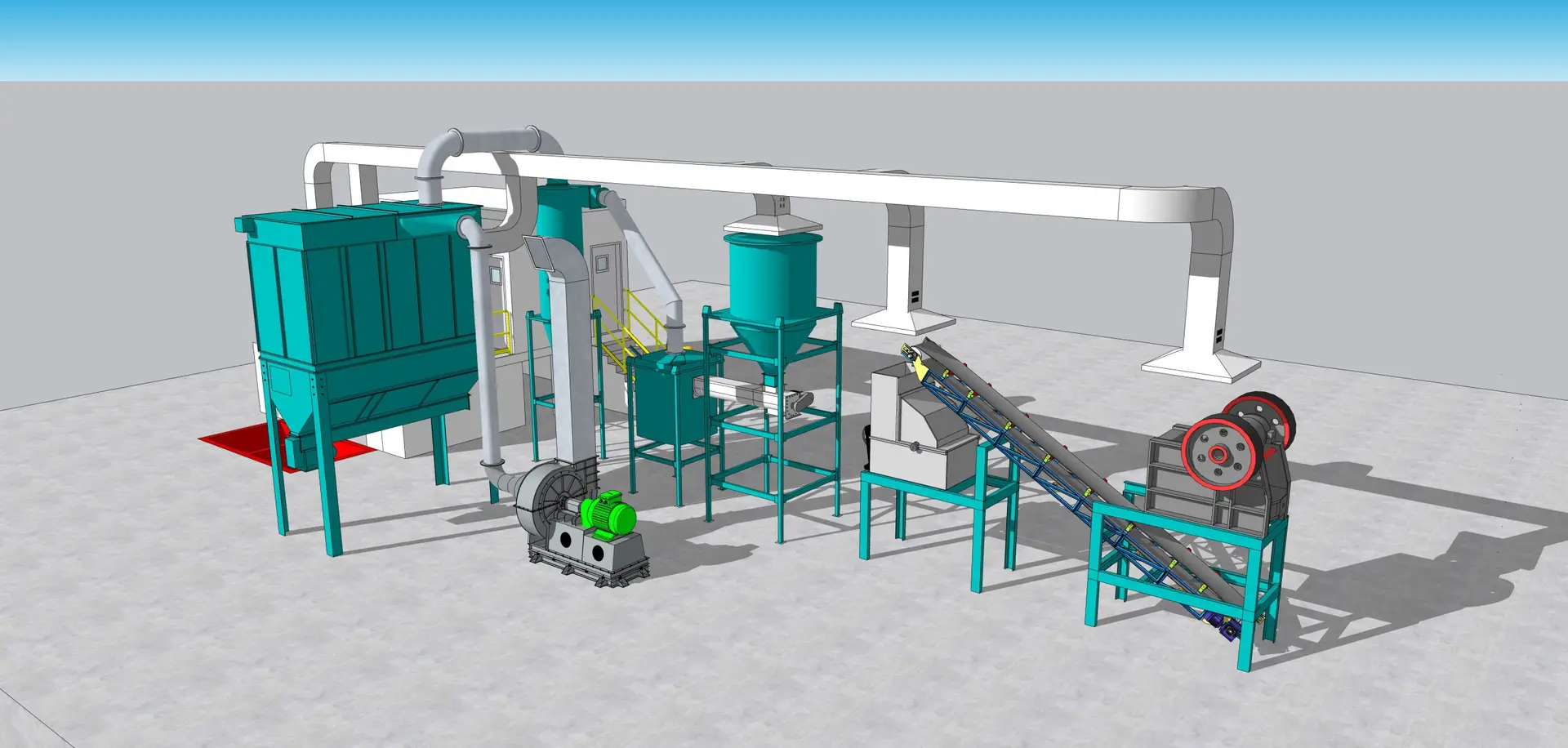

NonFM doesn’t rely on flotation alone. Its facility in Las Cruces will combine high-temperature smelting, dry and wet concentration, and flotation as a staged, flexible system. This allows the company to match processing routes to material characteristics—maximizing yield, minimizing cost.

Conclusion: A Game-Changer for Industrial Waste

Froth flotation, once limited to sulfide ores, is now being redefined by companies like NonFM as a core tool for circular mineral recovery. In the age of sustainability and resource scarcity, recovering metals from slag using flotation isn’t just possible—it’s essential.