We are proud to announce that we are in the final stages of setting up a high-fusion smelting system with a capacity of 1 ton per day, supported by a 20 tons per day crushing and milling line. This integrated operation represents a significant step forward in combining efficient mineral processing with advanced laboratory analysis under one roof.

High-Fusion Smelting: 1 TPD Capacity

At the heart of our operation is a modern induction-based smelting furnace system, designed for high-fusion processing of complex ores and concentrates. With 1 ton per day throughput, the system is engineered for precision, reduced energy consumption, and recovery of valuable metals from challenging feedstocks. This platform allows us to test and scale a variety of ore and slag sources while maintaining consistency in metallurgical quality.

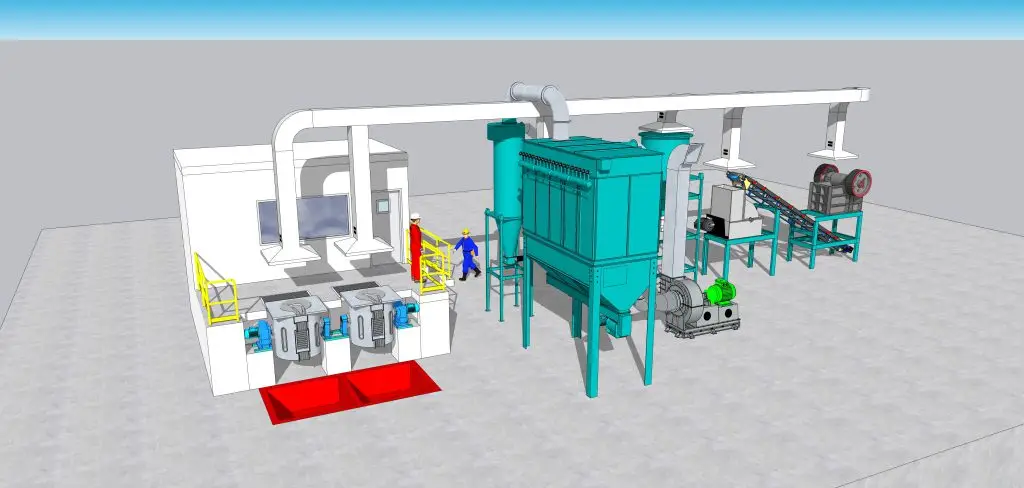

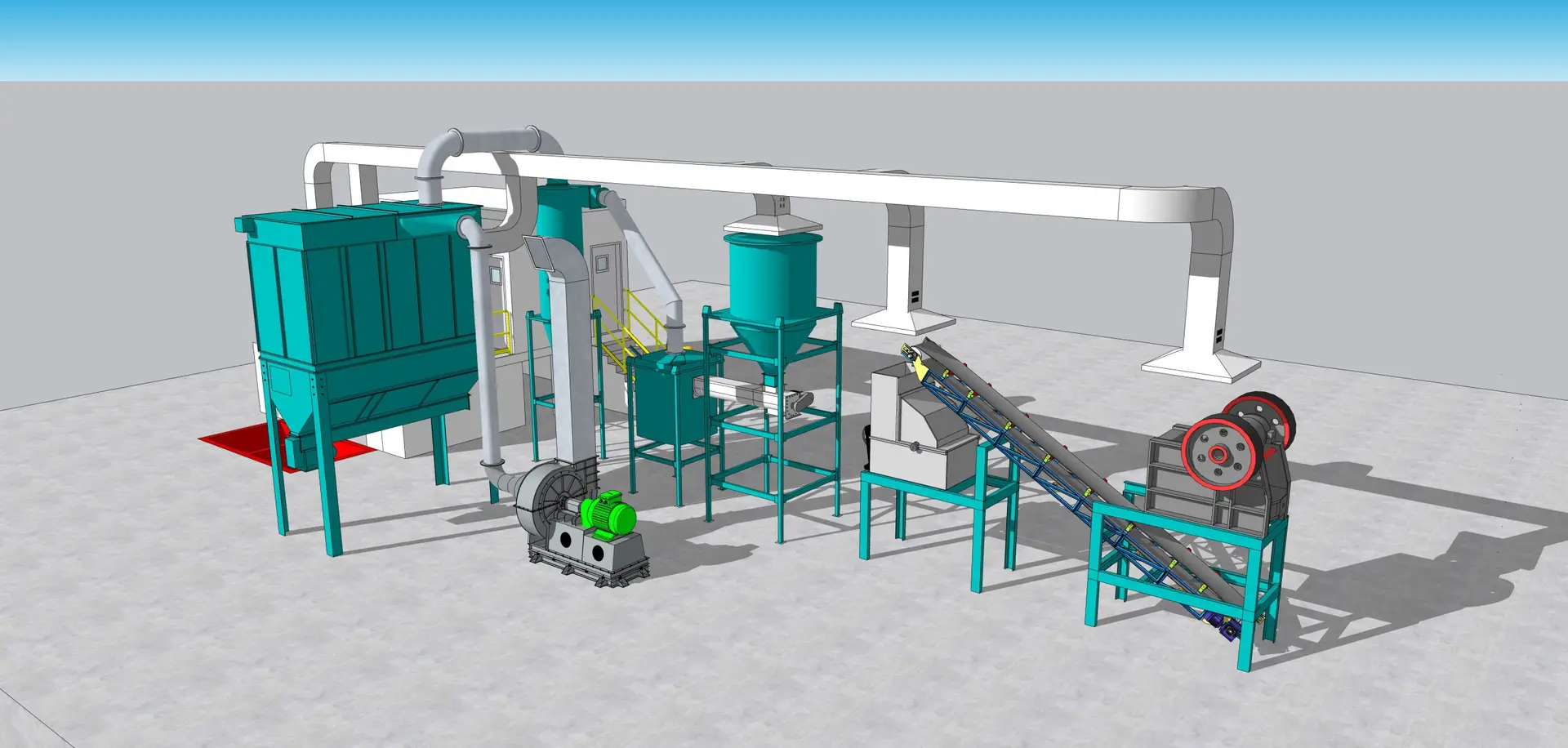

Crushing and Milling: 20 TPD

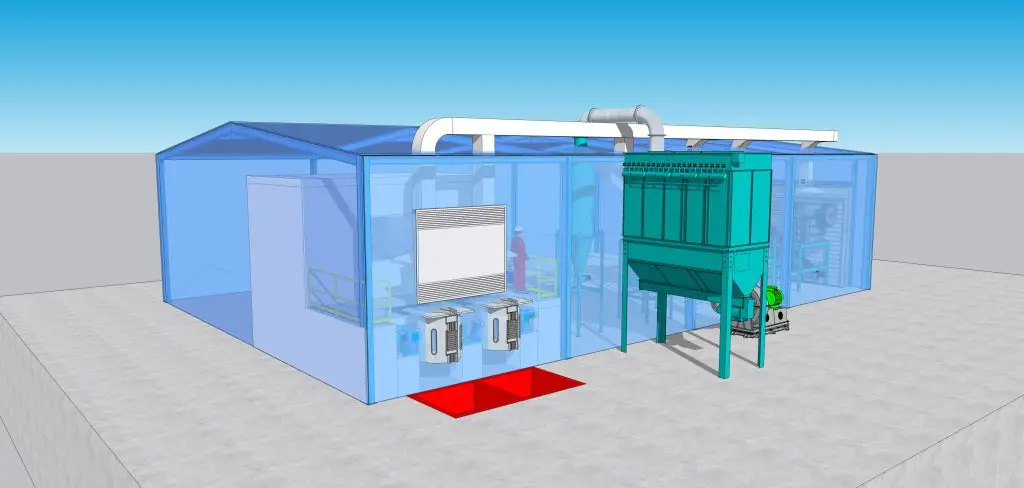

To support smelting operations, we are installing a 20 tons per day crushing and milling line. This system includes primary crushing, fine grinding, and particle size control tailored for optimal downstream metallurgical recovery. The modular design provides flexibility for both bulk sample preparation and pilot-scale continuous production.

Advanced Laboratory Facility

Recognizing the importance of in-house analysis, we are equipping a modern laboratory on-site to carry out our own mineralogical and metallurgical assays. This facility includes:

Fire assay for gold, silver, and PGMs

Wet chemistry and solution analysis

XRF/XRD for rapid elemental characterization

Pilot-scale test equipment for process optimization

This combination of production-scale capacity with research-level analysis gives us the ability to close the loop between field samples, processing, and final recovery in record time.

Looking Forward

With this infrastructure, we are positioning ourselves as a leader in eco-friendly, high-efficiency mineral processing. Our system not only addresses today’s industrial needs but also provides a platform for scaling up into larger operations, creating a bridge from pilot plant to commercial-scale deployment.